Request For Modeling Advice -arraying Pattern Around A Surface

Posted : admin On 26.09.2019Let's be honest, 3D printing can be quite tricky. Home 3D printing technology is still immature and 3D printing beginners who just bought their first machine are faced with a multitude of challenges when it comes to getting reliable and repeatable 3D print results. It is clear that a bit of expert guidance won't hurt! That's why we reached out to some of the top 3D printing experts and asked them the following question: What are your top 3 helpful tips for the new 3D printer owner? We asked the experts to share the knowledge and insights they have gained while spending hundreds of hours 3D printing and accumulating their fair share of failed prints.

- Request For Modeling Advice -arraying Pattern Around A Surface Line

- Request For Modeling Advice -arraying Pattern Around A Surface Crossword

These 3D printing tips are irrespective of any 3D printer model or brand such that they are broadly applicable. We have included a link back to each expert's website and social media profile in case you'd like to learn more about them and the work they are doing. Before we dive into the answers, we want to THANK all participants for sharing their hard-earned experience so freely.

Write an Article Request a New Article Answer a Request More Ideas. We use cookies to make wikiHow great. By using our site, you agree to our cookie policy.

Grab a pen, take notes and implement the info. Help to spread the word and share this post with your friends and fellow 3D printing enthusiasts!. First, make sure that you understand that 3D printing at home is still not yet 'ready for the average Joe', despite the hype that many brands brag about. Understanding how it works is (still) a must, as much as a natural tendency to be curiosity and to like tinkering. Only a few reliable printers may work out of the box (kits are often tricky). And even if you are lucky and if it works out of the box, you will have to solve complex problems soon or later, that are time and nerve consuming.

Oct 17, 2012 - “Fat models” cause maintenance issues in large apps. (read: features!) to your application, the goal is to spread it across a coordinated set. Sure, it looks cleaner at the surface, but the junk drawers actually make it harder. A smooth, polished tool surface will allow the part to eject with less draft than a standard tool surface. Consider the fabrication of the hollow plastic box seen to the right. Once the plastic has hardened around the mold, the mold must be removed.

Be patient and inventive!. Do not print with a badly calibrated printer! Some printers are even delivered while not properly tuned, and price is not always a safe indicator! Check that everything is square, that the pulleys or belts are not lose, that the is level. Keep it clean.

Right now, the forums are filled with years of ideas, problem solving and interesting experiences. So 99% of your own are probably already discussed in length. The hard part is to recognize it in the first place, which is often not obvious! Experience and practice are a must, and you will eventually know enough that something goes wrong by the sound it makes!. Never focus too much on one single issue.

These machines are complex, and a trouble often arise from multiple reasons. A slipping filament may not only be caused by a 'bad' hobbed bolt or driving system, but also by an obstructed, a wrong feed value, a too low (or too high) temperature.or a combination of all these! As a general rule, do not expect things to go better if you have to abuse any parameter (e.g. By raising the temperature or flow rate). Start printing with low temperature and low speed, and only then drift slightly around the settings so you learn the combined effects: each filament has its own best set of values. Knowing how to diagnose the printer is a huge win for a full experience. Richard Horne a.k.a RichRap RichRap is an Electronics Engineer, Product Designer, Salesman, and Problem Solver who has been working in a wide range of industries and applications, across many platforms and technologies for the last 20 years.

Rich's interest and passion for 3D printing started in 2009 after visiting the project website. He started blogging, designing and developing with 3D printing shortly after.

Having built his first 3D printer, The RepRap Developments And Further Adventures In DIY 3D Printing Blog started on Sunday,13th September 2010 and has continued ever since. Blog: Follow Rich on. My first general tip would be that when you first get a 3D printer up and running, print out lots of 20mm cubes. It's quite a boring object, but it can help ensure you have a well setup and calibrated machine. You can print these solid to test for over extrusion and size calibration. You can also print hollow to test for accurate perimeter width settings in your slicing program. This will also ensure better and more accurate hole size, model features and improved strength of parts when you have the perimeter width setting and flow rates correctly defined.

My next tip, which really follows on from the above, would be to get comfortable with nozzle to print bed adjustment - This sounds obvious but it's still the main thing people don't spend enough time on when getting started. And it's so important for successful printing. Really don't ignore this aspect even if you have a 3D printer that automatically adjusts for a bed that's not vertically straight / level / tram / flat - these are all names used to describe a printing surface that is setup correctly. The more time you spend with your particular 3D printer, the more you will learn on how best to adjust it, and hopefully then keep it calibrated so you don't need to tweak it all the time. The auto-level compensation in some 3D printers can add adjustments that make some prints look of a lower print quality or due to the compensation it may emphasize the layering especially on vertical surfaces. So try to get everything vertically straight. The X,Y and Z axis should all be at a 90 degree angle to each other.

This is actually still quite hard to do and prove. Printing cubes and testing them (measuring and checking it they are straight) after printing with a set square is still the best way to check it's all setup correctly. Believe me, getting this setup and calibrated will save you so many print problems and adjustments later on. Then the same thing goes for print size calibration. When you print a 20mm cube, is it 20mm when measured?

- if not check if it's a calibration issue with the machine. This can also be tricky to track down. Sometimes it may require an adjustment in the steps per millimetre settings in the firmware (more likely if you have built up a 3D printer yourself or from a kit) and very often it's just down to over extrusion of material causing an over-stuffed object. Experiment with extrusion rates, In my experience it's often better to be 10% under extruding than any level of over extruding. And a surprising amount of people are over-extruding without even realising it. Jim Rodda a.k.a. Zheng3 Jim 'Zheng3' Rodda is an artist best known as the designer of, the Open Source tabletop wargame designed to advance the state of hobbyist 3D printing through competition and player-directed evolution.

Jim blogs about all things 3D printing at Zheng3.com, and has dozens of models available for free download at. When he's not designing models or writing tutorials, Jim trains in Brazilian jiu-jitsu, studies Mandarin Chinese, and plays with more Barbie dolls than is healthy for a man his age. He's also planning a new crowdfunding project for later in 2015. Blog: Follow Jim on. Win if you can, lose if you must, but always cheat.

Request For Modeling Advice -arraying Pattern Around A Surface Line

Your goal is to get a completed object off the print bed, not to have a magical machine that runs without human intervention. Use whatever tricks and cheats you can think of to make sure the print sticks to the bed. I've been known to pause the printer and super glue the first layer to make sure it doesn't go anywhere, especially on large, flat prints. A little post-processing with, filler, and paint goes a long way towards making nice objects you'll be proud to show off. Eat the elephant one bite at a time. Don't try to print too many discrete objects at once. One little widget getting dragged around by your tool head will quickly ruin the rest of an extensive multi-part print.

If you're designing a model from scratch, test-print the tricky bits first by carving them off the main model. Autodesk Meshmixer is great for slicing a complicated model up into pieces. In theory, theory and practice are the same but in practice, they're different. Digital models change when they're birthed into the analog world.

Cooling plastic will shrink an otherwise perfectly designed dovetail joint. Your printer might lay down a slightly wider first layer, throwing off your design by a few microns. Your haste to pull a warm print off the bed might warp it into unusablity. Resist the temptation to print a scale model of a variable-speed transmission your first time out. Start with something simple and fast like instead until you gain experience with your printer's quirks and foibles. And please, for the love of whatever powers you hold dear, please don't print any more Yoda heads. 3D printing isn't quite like magic yet.

It's getting there, but for most printers some careful thought about how your model will print is the key to getting good results. Printers (like most of the open source ones are) can't print on thin air, so models that have large overhangs will print much better if they are either reoriented to lie down on the print bed, designed to use automatically generated support for overhanging parts, or divided into separate pieces that can be printed without support. It takes a little practice to get the hang of what works best for your models, but the results are worth it!.

Get a little. They can be purchased for less than $10 on Ebay or Amazon, and are required to accurately measure filament, calibrate your printer, and to adjust your utility - oriented prints for a perfect fit. They really come in handy for measuring stuff that you are trying to model too!. Learn how to design your own models right away. Using is a little tricky at first for the beginner, but you will need to be able to design your own models from scratch to realize the potential of your printer.

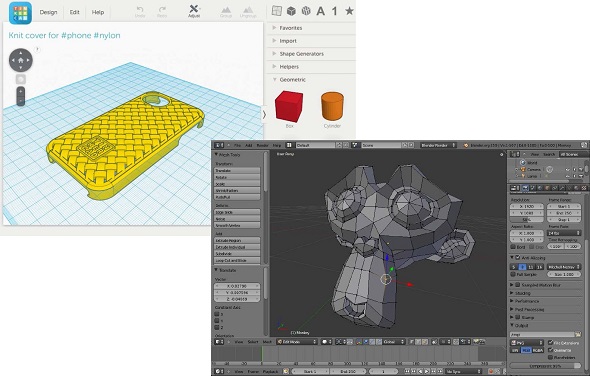

Making other peoples models is fun, but soon enough you'll want to tweak this, change that, or just start over from scratch with a better idea. Even though the learning curve is a little steeper, you'll be better off if you quickly go towards a full featured 3D program as soon as you have mastered the basics. You'll outgrow the “super easy” software really fast if you design much, and there are a lot of great, free software choices out there. For making functional items, a good path is to start with Autodesk 123D Design (free), as it will set you up with the skills to graduate to a full featured suite like Autodesk Inventor (free for student use!). If modeling characters or ornamental items is your thing, something like Blender might be a better choice.

Philip Cotton Philip Cotton is the founder of the 3dfilemarket.com an independent marketplace to share and sell verified 3D printing designs. He is also a full time educator who has been awarded the 3dprintshow educational excellence award for two consecutive years for his teaching of 3D printing to high school students. He has advised the BBC on 3D printing and also taught university students about 3D printing in education. He was named as one of the top ten people to watch in 3D printing in 2015 along with Makerbot's Bre Petis and blogger Rachel Parks. Philip is an education ambassador for beethefirst 3D printers and is also a regular contributor to the 3D Printing Association.

Web: Follow Philip on. Choose a 3D printer that has good support available from the manufacturer, preferably one from a local supplier. This way if you need help then you can access it on a local level rather than national level. If you buy a cheap printer from eBay and its shipped from China then if something goes wrong it could prove very frustrating to fix. If there's local support then this will be far easier.

Find a good forum to engage in so you can see what 3D printing is all about. Members of these groups are really helpful and they can be a great learning experience. 3D printing is emerging at a rapid rate and keeping up to date with this will help you along the way. Learn to start designing using CAD. There are many to use e.g.

SketchUp, Tinkercad, Autodesk Shapeshifter etc and start to model your own basic designs. There is nothing more satisfying then designing something yourself and then 3D printing it yourself. You can then even share these designs or sell them on the many file sharing websites out there.

3D Printing Philosophy for Beginners: A 3D printer is a person not a thing. It is the combination of the person and the hardware that produces beautiful 3D models. The journey to becoming an experienced 3D printer can be difficult but is equally rewarding. 3D printing challenges the beginner to stretch themselves as a designer, maker, scientist and artist. Tips and tricks may ease the journey but ultimately the beginner has to take each step themselves.

The first step is the hardest. Unboxing new hardware and making the first successful print is the most challenging part for a new 3D printer. Inspect the printer to make sure it wasn't damaged in shipping. Rods can be bent, extruders can be jostled out of alignment, connections can come loose, glass build plates can crack, etc. Look for anything obvious that might be shipping related and report any issues right away.

Request For Modeling Advice -arraying Pattern Around A Surface Crossword

Setup the printer according to the manufacturer's instructions. It may seem straight forward but there are often restraining straps or brackets that need to be removed. Follow the manufacturer's recommendations for software and settings for the first print.

Level and Calibrate the printer. It may be tempting to skip ahead and start a print but that can result in a scratched bed surface and jammed nozzle. your model using the manufacturer's recommended and settings. Try to adjust one thing at a time between prints and keep notes about the settings and effect on the print. Label test prints with a sharpie and take photographs. Don't use transparent filament for your first print. Clear filament is hard to photograph.

You don't want the first photos you share of your 3D models to be out of focus. When photographing your models, use lots of light while avoiding glare.

Try bouncing lights off a light colored wall or use an. Use the sharpen command in your image editor to bring out the details of prints. Having a well lit photo with sharp detail comes in handy when asking for advice online or showing off your prints.

Buy a roll of the manufacturer's recommended filament when you purchase your printer. New printers typically come with a small sample roll of filament.

The samples can be hit or miss in quality. Being able to switch to a different roll of filament can be a useful tool.

Cheap filament can be great but is more likely to be a headache when starting out. Ideally, buy two rolls of contrasting colors that look good together. Having two contrasting colors allows for mid-print filament swaps and makes for great multi-part models. Printing with on is a great starting point. Be sure to wipe down the print bed with an alcohol wipe to remove any grease or grime from the factory before applying the tape. Getting the perfect extruder height is critical to great prints.

I prefer the z-level to be set so that there is a very faint impression left on blue painters tape when removing a PLA model. Invest time into your skills! Don't get trapped in the 'I need so see if that item is available on Thingiverse or Youmagine.com' dead end. Invest as little as an hour per week into your favourite CAD or modelling app and become a true creator of your very own items.

Fix the weakest links until everything is perfect! 3D printing is like a chain, if one part of your printer isn't doing a perfect job, you won't get great results. By watching closely and getting in touch with the community or vendor you'll always find a way to improve the hardware, software or firmware. Never settle 😉. Print responsibly! Seriously, ensure good ventilation of your print cave and install a smoke detector nearby.

There are too many fancy (and potentially toxic) materials and new (and potentially not fully tested/certified) machines on the market that you can't be sure that everything is as safe as your washing machine. Charles Fried Charles Fried is a product designer aiming to be the forefront of the digital manufacturing revolution. He believes in a world where items are traded in a digital format and where automated customization would be at the center of the design process, increasing both personal value and functionality. Charles is currently studying for my MSc in Adaptive Architecture whilst also running Prodpoint.com a design & 3D printing service. Work seen on: Shapeways, Thingiverse, Reuters & many more Web: Follow Charles on. Focus on user experience instead of metrics when buying a 3D Printer.

Maybe you're still deciding on which machine to buy as your very first 3D Printer. You're probably overwhelmed by the amount of manufacturers offering 3D printers in more or less the same price range. There's one big pitfall in your mission to compare them: comparing metrics which don't mean anything to you yet. You have probably put your shortlist to decide which offers the best value for money.

On top of that list you've probably put measurable specs like speed and layer height. Because faster is better and smaller layers mean better prints? Possibly, but it's irrelevant. You'll want to know how accurate a printer is at a certain speed, but no manufacturer will tell you, because the answer is a whole lot lower than the listed maximum speed. Compare it to buying a car: you won't buy a car that's very fast but performs terrible in corners. That's why you test-drive a car instead of buying one based on the specs in the brochure. It's all about user experience, something that is impossible to measure and largely based on personal taste and experience.

Ideally you want to test-drive a 3D printer for a few days before buying, but no manufacturer let's you do that and commercial places to test the 3D printers are still scarce. At this moment in time you do have a few options: Try to find of the 3D printers on your shortlist, like the ones I write.

Do search for actual hands-on user review, not paraphrased press releases by tech journalists. Another - and even better - option is to do a quick search on 3D printer network site - like 3Dhubs.com - to see which printers people in your neighborhood own! Send a same small design file (from Thingiverse.com for example) to a few Hubs and choose to pick up the result. When you do, chat with the owner about his or her 3D Printer.

He or she will probably take all the time to talk about the pros and cons and there's a good chance you can see the printer in action. This is especially great, because it allows you to hear the amount of noise it makes. That's one thing I have discovered when testing different printers: they might be called 'Desktop 3D Printers' but some are so loud I wouldn't want them anywhere near my desk. This way you can compare print quality and come to know a lot about the user experience of those printers, all within a week and for a few bucks. Explore the world of exotic filament. When I started 3D printing, filament choice was basically limited to and PLA. Things have changed a lot since then and over the past year many new filament manufacturers have emerged.

They're developing new materials as well as blending existing ones with all kinds of non-plastic particles. To get an idea about the great variety, look at the I wrote a few months ago. I'm currently in the process of updating it, because the amount of filament has more than doubled since I published it.

The thing I like about many of these new materials, especially the composite blends, is that they enable your 3D prints to be more than just plastic trinkets. They allow you to go beyond printing prototypes and make stuff that doesn't look and feel 3D printed anymore. For example, printing with filament that is a blend of PLA and metal particles - like - can result in objects that seem to have been molded instead of printed, especially after polishing. At this moment 3D Printing Filament is evolving much faster than 3D printers themselves. And in my opinion these filaments are the sole reason FFF (Fused Filament Fabrication) 3D Printers can stay relevant, because I expect other technologies - like or DLP printing - to start dominating the prototyping market very soon. Explore design tools and start creating yourself! When making your very first 3D print, it doesn't matter what object you chose - it's magical!

But while many casual 3D printing enthusiasts keep searching for new things to print on sites like Thingiverse, I like to encourage anyone to start exploring the vast variety of that allow you to design your own stuff. This market is evolving even faster than 3D printing and filament combined and it needs to, because easy-to-use creation tools are essential to briging 3D printing to the masses. There are many desktop-, browser- and tablet-based apps to design your own objects without having any experience with 3D modeling or CAD software. A good place to start is the free Autodesk 123D software range.

The first time you have 3D printed something you have designed yourself, metrics like printing speed become meaningless and you'll experience that magical feeling you had when you made your first 3D print tenfold. And do share them with the community, because when other people start printing your design and posting photos of it, 3D printing reaches a level of community interaction that no other technology offers: your designs physically entering - and maybe even enhancing - the lives of people around the world.

June 9, 2015 Many thanks at all for sharing their expert tips. Great stuff to have a lot of the experienced colleagues in one thread. Some experiences from my side after 4 years of practice with 3D Printing, dozens of facilitated workshops and talks about 3D Printing: 1. Be open to experiment and don’t get frustrated too fast.

Especially consumer 3D Printing is not Plug & Play. Watch and try to understand the influence factors on the printing quality.

The quality of the 3D printed objects depend on a lot of factors like material, printing temperature and speed, mechanics, object geometry, other printing settings. Printing the same model with various settings (of one parameter per print only) e.g. 5 degree different temperature making notes of the settings and observations and marking the printed object with a number helps a lot to understand and compare the results. Exchange with other people about your experiences in forums, 3D Printing interest groups, meetups, at FabLabs or Makerspaces etc. The 3D Printing community is very supportive and young i.e.

Even the experienced guys have only a few years of know how and have very often started with the same questions and challenges. Leon de Oliveira - June 17, 2015 Michael Sorkin says the following “Start slow and look up the basic knowledge around the extrusion process, overhangs supports and retraction.” Where would I find this information. I am exploring communities, but I am looking for a guide to describe the different settings on slicer programs and how they pertain to the printer. What are the minimum/maximum/recommended settings for my slicer?

Is it different for different materials? These are the questions that I have that I am looking for answers for. I am trying things out with my schools printer, but I teach full time and don’t have the time to try everything out. Norman Morton - July 4, 2015 Just to begin with, Let me say a big thanks for all of you that happily share their knowledge of this still emerging form of Printing for the home user like me Thanks a whole lot to you all.:-) I have just pressed my buy button for a 3D printer being the New 2014 Wanhao model D4S. This is my first attempt at this 3D printing lark but am really looking forward to my steep learning curve that is to follow. I am still looking at various Software that I will need for my new printer (I am totally new to CAD or Slicing e.t.c or anything of that sort so know I will have my work cut out in the beginning, but hopefully this will get easier as I progress:-)).

I will certainly be coming back for more help in the future for sure & It’s great to know there are sites like this that will help Novices like me make headway in this 3D printing thing I’ve taken on Thanks again all.:-).

Looking to have a stash of backup parts on hand for your Gigabot? The Gigabot Replacement Parts Bundle includes all of the parts from your Gigabot that will need to be replaced due to normal wear and tear, so you have them when you need them. The bundle includes one extruder (two for dual extruder), one Azteeg x3, one Viki interface, two motor drivers, one single or dual heater, one thermocouple daughterboard, one X/Y Upright, one spare fan assembly, one left hot end (and one right for a dual extruder), jumper cables, one TC1 thermocouple (and a TC2 thermocouple for a dual extruder), and two Y and Y axis carrier supports. It’s most likely that you are printing via USB from your computer. There are a number of computer processes that can interrupt a print.

Make sure to turn off any auto-updates which may restart your computer. Also turn off sleep mode, and screen savers. Using other processing intensive programs can also contribute to an interference. Ultimately we really recommend using the SD card function from your Viki and unplugging from the computer altogether. This will eliminate any potential issues from interference. Is user-friendly software and a highly recommended tool for optimum output of 3D prints on Gigabot. Using this software, re:3D engineers develop material printing profiles and use this workflow to adjust settings for a wide variety of materials on Gigabot. re:3D is a Simplify3D software reseller and as a result, the Gigabot printing profile is available through the software package download.

Simplify3D is a one-time purchase for two licenses at $149. There a few options out there; the open source versions available are pronterface as a printer interface, and Slic3r as a slicing engine. Another version available is Repetier, which combines Slic3r with it’s own print interface. No matter which program you chose to use for your Gigabot, don’t forget to download the presets from the.

First make sure that your bed is level. Check out these helpful resources:.

Print in Z is a 3D printing surface that replaces the need to use blue painter’s tape. Helps with print adhesion as well as overall print quality. Print in Z is available from for $135. If you have a heated build plate, now is definitely a good time to use it!

We’ve seen popular community alternatives such as blue painters tape, Kapton tape or Buildtak. Print in Z is a great all-around print surface for anything from simple to extremely difficult print jobs and is available in the re:3D store! Gigabot 3.0 introduces dual extrusion print using two direct-drive extruders, loaded up with a re:designed cold-end, assembly, and high-temperature re:3D hot-ends.

Tested and verified through countless prints in-house and with Gigabot 3.0 beta super-users. As part of our commitment to ensure your Gigabot is never obsolete, is now available as a retrofit kit. Dual Extruder Trolley Update Includes:. Simplified Trolly Assembly. Custom Cold Extruder Blocks. 0.4mm E3D Hot-End & Thermocouples.

Cable Carrier in X, Y, and Z. Direct-Drive Geared Stepper Motors. Filament Detection & Firmware.

Z-Limit Switch Relocation About re:3D Hot-Ends: Capable of printing any thermoplastic melting below 350C, this all-metal extruder opens the door to a wider variety of materials, including high-strength and high-temperature filament. The re:3D all metal extruder provides a considerably longer lifetime than the previous model – roughly quadruple (2000hrs vs. Gigabot can run unattended. Our longest print to date is 122hrs (or 5 days, 2 hours, and 44 minutes). Using the Filament Detection feature released on generation Gigabot 3.0, your Gigabot will pause mid-print and wait for user input when it runs out of material.

Quote valid for 30 days. Payment to be made in full in advance in order for product to ship. Refused Gigabot shipments will be charged return shipping and a $1000 restocking fee. Orders paid with a credit card or PayPal will be charged a 3% processing fee. Duty & tax are obligation of buyer. If this transaction involves an export of items from the United States (including, but not limited to, commodities, software or technology) subject to the Export Administration Regulations, such items were exported from the United States by Seller in accordance with the Export Administration Regulations.

Customer agrees that it will not divert, use, export or re-export such items contrary to United States law. Any diversion of an item contrary to US law is strictly prohibited. Customer expressly acknowledges and agrees that it will not export, re-export, or provide such item(s) to any entity or person within any country that is subject to United States economic sanctions within the control of the Office of Foreign Assets Control without obtaining prior authorization from the United States Government. All products may be returned within 30 days of receipt of the item. Items that are returned within 15 days of receipt in unused condition shall be subject to a full refund. If the item is returned within days 16 through 30 or in used condition, there will be a 10% restocking fee deducted from the refund. All Final Sale merchandise cannot be returned.

Other nonreturnable purchases include digital content, gift packaging, memberships, completed services, consumable items including 3D printer filament, and items returned that are damaged, unsanitary or missing major contents. We warrant the Gigabot against defects in materials and workmanship under ordinary use for 30 days from the date of receipt. This limited warranty applies only to hardware components of the Gigabot that are not subject to accident, misuse, neglect, fire or other external causes, unauthorized use, alterations, or repair, installation or enabling of unauthorized software or services, unauthorized alterations to the Gigabot or unauthorized resale. If we elect to do a replacement of your device, we will place the cost of the device (the then prevailing MSRP plus tax) hold on your credit card. We will charge the full retail price of the replacement device if we do not receive your original device within 21 days of delivering your new device. Information has been carefully checked and is believed to be accurate; however, no responsibility is assumed for inaccuracies. Re3D reserves the right to make changes without further notice to any products to improve reliability, function, or design.

Re3D does not assume any liability arising out of the application or use of any of its products; neither does it convey any license under its patent rights of others. The filaments we use are listed below. We have not performed an destructive testing and cannot guarantee any particular mold shape or design to withstand a particular rated load. PLA – Glass Transition Temperature: 60-65 °C, Melting Temp: between 173-178 °C, and Tensile Strength: 2.7-16 GPa. ABS – Maximum Temperature: 176°F 80°C Minimum Temp: -4°F -20°C, Melting Temp: 221°F 105°C Tensile Strength: 4,300 psi. Taulman 618 nylon specifications can be found here: Taulman 645 nylon -Taulman T-glase PETT –.